Case Study: Using the Factory Management Module.

The Challenge

Fashion and textile brands often work across complex global supply chains, collaborating with dozens — if not hundreds — of factories. Managing this network is a major challenge. Brands don’t just need to track current suppliers but also keep tabs on potential future partners. Critical data like audit results, wage information, environmental practices, certifications, and product capabilities are typically scattered across spreadsheets, emails, or stored with individual team members.

The result? A lack of clarity, duplication of efforts, and missed opportunities for better decision-making and responsible sourcing.

The Solution

To address this widespread industry issue, we developed the Factory Management Module — a powerful feature within The Chain platform designed to centralise and streamline factory oversight.

This module allows brands to bring all factory-related data into one secure, searchable place — whether they are actively working with a supplier or simply considering them for future use. By doing so, teams can make better-informed decisions, reduce admin time, and move closer toward meeting their sustainability and due diligence goals.

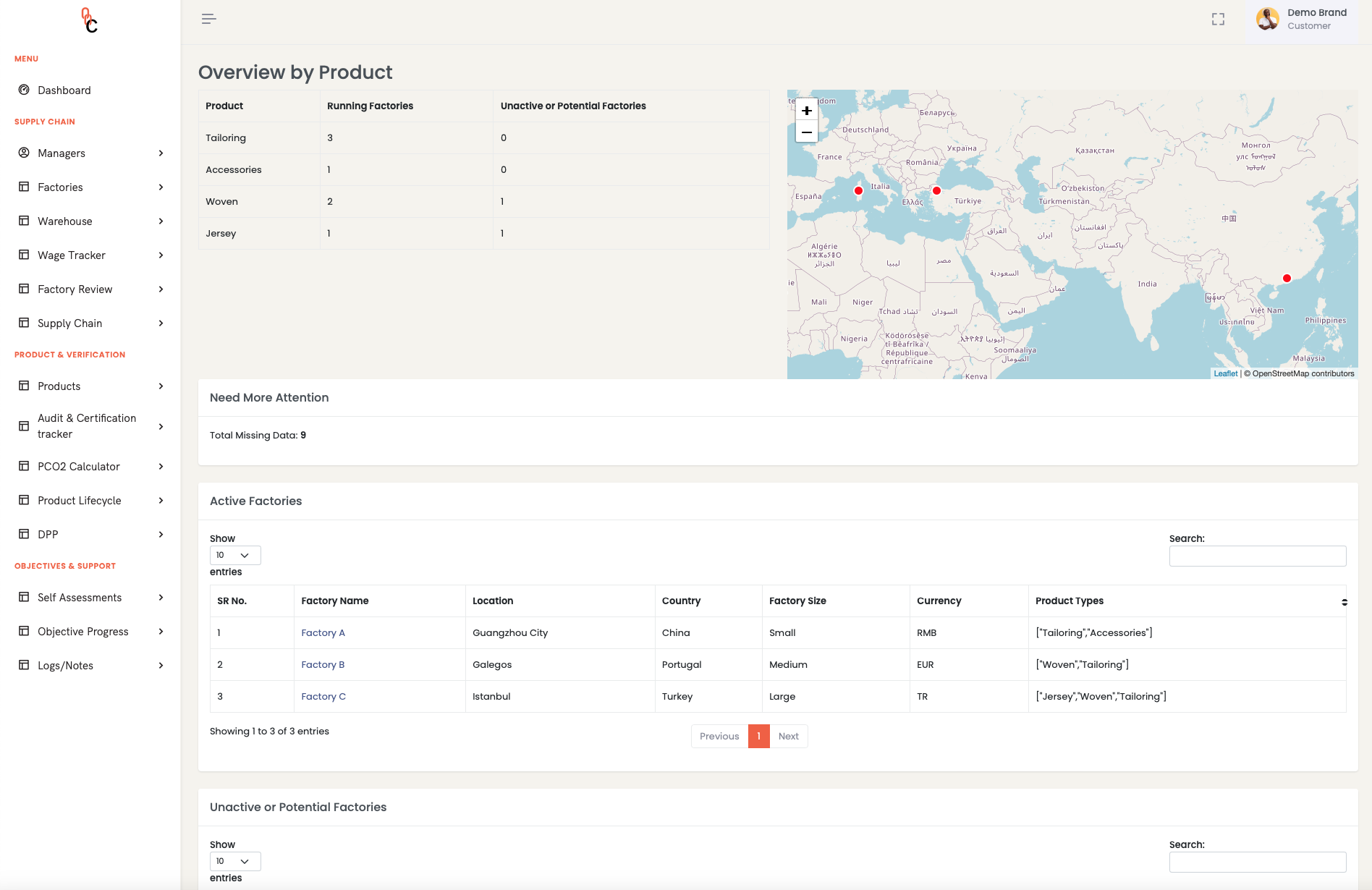

Screenshot of The Chain Factory Module, showing all factories in one place, even the potential factories.

Key Benefits

All Factory Information in One Place

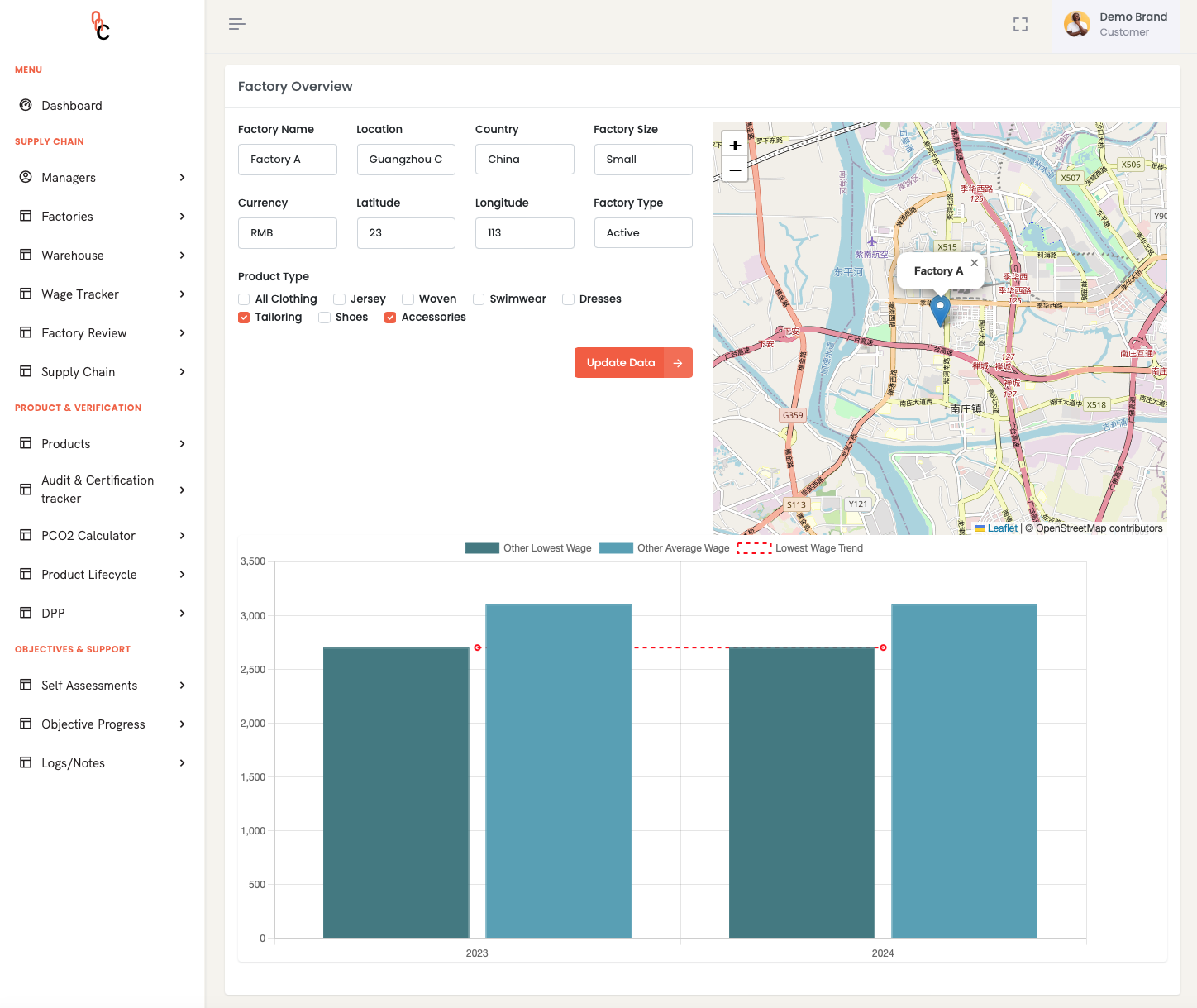

No more chasing down documents or digging through old folders. Brands can upload or sync existing factory records into a single dashboard — including details like location, contact information, audit history, wage levels, product capabilities, and more.

Powerful Search & Tagging

Looking for a denim factory in Bangladesh with an SA8000 certification? Or perhaps a potential knitwear supplier that has passed a Living Wage audit? With smart search and filters by product type, country, or compliance features, the module makes it simple to identify the right partner.

Screenshot of The Chain Factory Module - Showing a factory example

Factory Reviews That Go Beyond Checklists

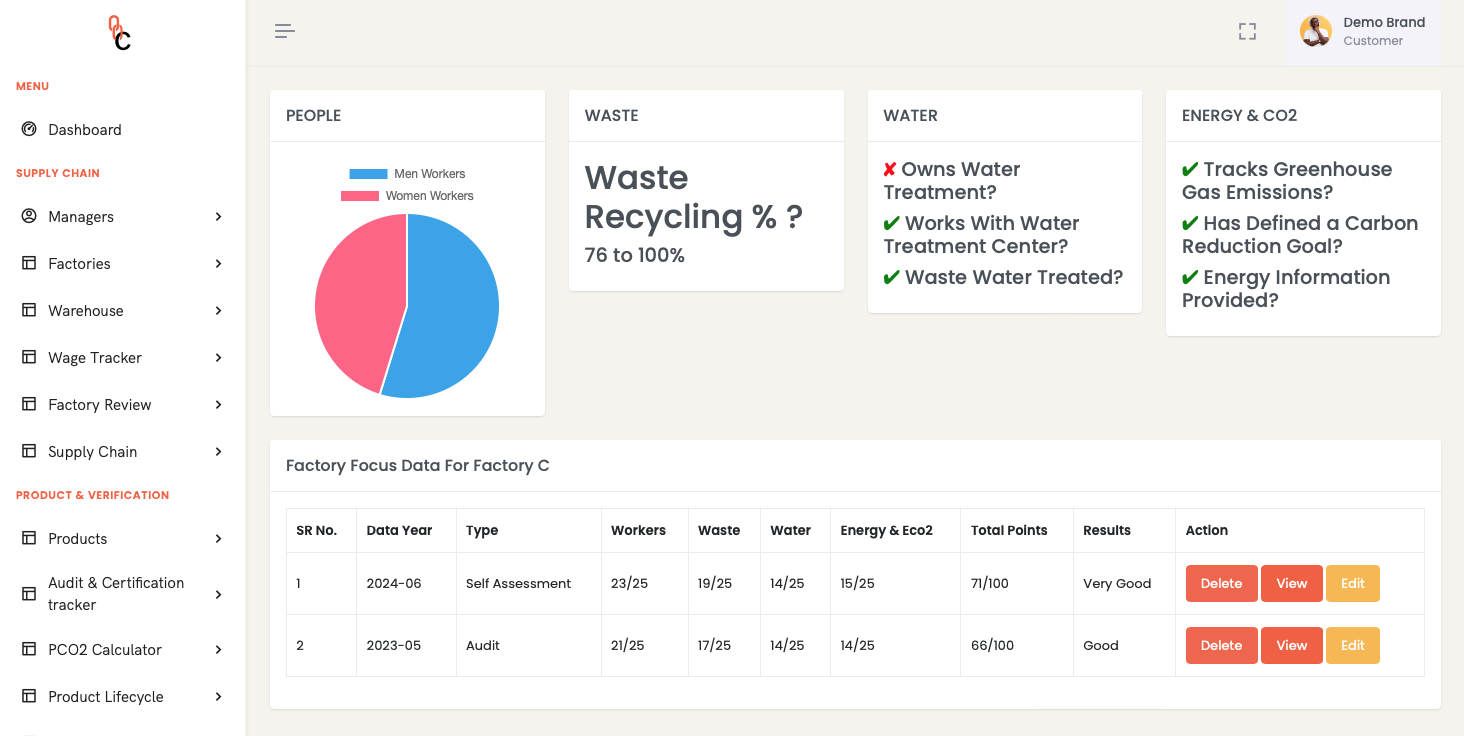

Each factory has a built-in review generated from audit data and self-assessments. This covers key pillars such as:

People (e.g. working hours, wages, gender equity)

Waste (e.g. chemical and textile waste management)

Water & Energy (e.g. consumption and efficiency practices)

CO₂ (e.g. emissions data, reduction efforts)

These are pulled into a clear overview score, helping teams quickly assess performance across both social and environmental dimensions.

At-a-Glance Compliance & Wage Overview

Want to know which factories are exceeding wage benchmarks? Or which are pending re-audits? The module provides a snapshot of the most important metrics — helping CSR, sourcing, and compliance teams stay aligned and up to date.

Screenshot of The Chain Factory Review module, showing a overview of all the factories recent self assessments or audits.

The Impact

Since launching the Factory Management Module, brands using The Chain have reported greater visibility across their supplier network, improved sourcing decisions, and time saved across compliance and product development teams. By centralising key factory data, teams are better equipped to meet both regulatory demands and ethical expectations — with less stress and more confidence.